Specific Process Knowledge/Lithography/Descum: Difference between revisions

| Line 20: | Line 20: | ||

*N2 flow: 70 ml/min | *N2 flow: 70 ml/min | ||

*Power: 150 W | *Power: 150 W | ||

{| border="1" cellspacing="1" cellpadding="2" align=" | {| {{table}} | ||

| align="center" | | |||

{| border="1" cellspacing="1" cellpadding="2" align="left" | |||

|- style="background:LightGrey" | |- style="background:LightGrey" | ||

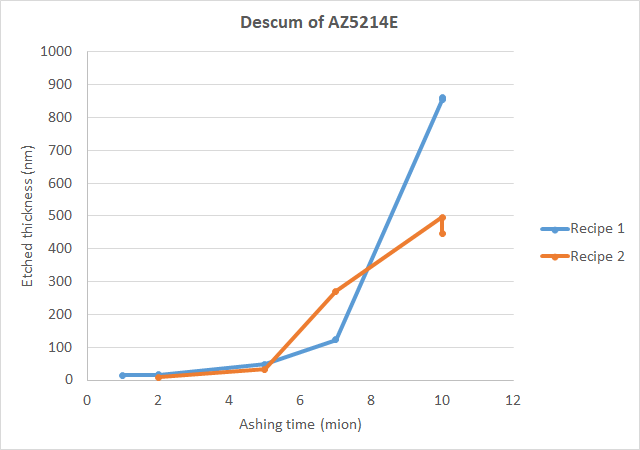

|'''Ashing time (min)'''|| 1|| 2 || 5 || 7 || 10 || 10 | |'''Ashing time (min)'''|| 1|| 2 || 5 || 7 || 10 || 10 | ||

| Line 26: | Line 28: | ||

|'''Etched Thickness (nm)'''|| 14.2 || 16.3 || 47.6 || 123.2 || 854.3 || 862.1 | |'''Etched Thickness (nm)'''|| 14.2 || 16.3 || 47.6 || 123.2 || 854.3 || 862.1 | ||

|- | |- | ||

|} | |||

|} | |} | ||

'''Recipe 2:'''<br> | |||

Note: Plasma asher was cold before use | |||

*O2 flow: 500 ml/min | |||

*N2 flow: 0 ml/min | |||

*Power: 500 W | |||

{| {{table}} | {| {{table}} | ||

| align="center" | | | align="center" | | ||

{| border="1" cellspacing="1" cellpadding="2" align=" | {| border="1" cellspacing="1" cellpadding="2" align="left" | ||

|- style="background:LightGrey" | |- style="background:LightGrey" | ||

|| | |'''Ashing time (min)'''|| 1|| 2 || 5 || 7 || 10 || 10 | ||

| 1 || 2 || 5 || 7 || 10 || 10 | |- | ||

|- | |'''Etched Thickness (nm)'''|| || 8.1 || 32.9 || 271.1 || 495.6 || 446.2 | ||

| | |||

|- | |- | ||

|} | |} | ||

|} | |} | ||

Conny Hjort & Jesper Hanberg | Conny Hjort & Jesper Hanberg | ||

Revision as of 11:20, 30 January 2023

Feedback to this page: click here

Descum results

Plasma asher 1

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager.

Descum of AZ5214E resist on 50mm silicon wafer. Wafer was placed horisontally in chamber on a 100 mm carier wafer.

Recipe 1:

Note: Plasma asher was cold before use

- O2 flow: 70 ml/min

- N2 flow: 70 ml/min

- Power: 150 W

|

Recipe 2:

Note: Plasma asher was cold before use

- O2 flow: 500 ml/min

- N2 flow: 0 ml/min

- Power: 500 W

|

Conny Hjort & Jesper Hanberg

September 2019

Descum of different resists, AZ5214E, AZ701 MiR and AZ2020 nLOF, on a single 100mm wafer was tested. Wafer was placed vertically in the middle of glass carrier. Recipe setting was the same as in previous test in September 2019: 70ml/min O2, 70 ml/min N2, power 150W, different ashing time 1, 2, 3, 5 and 7 min run. Plasma Asher was cold before use, we observed minor temperature rise during processing, but not more than 5 degrees. Starting chambers pressure was around 0, 5 mbar.

1,5 um AZ5214E resist

|

1,5 um AZ5214E resist placed horizontally in the carrier

|

1,5 um AZ701MiR resist

|

1,5 um AZ 2020nLOF resist

|

Plasma asher 2

Descum of AZ Mir 701 resist on 100mm silicon wafer. Five wafers were placed vertically in chamber.

Experiment parameters:

|

recipe 1

|

recipe 2

|

We can observe linear dependance of etched material on time after etching 7 minutes and more (recipe 2).

Jitka Urbánková & Jesper Hanberg

December 2019

Plasma asher 3

Plasma Asher 3 is specially used for control descum process after lithography. Please notice that you only can process one 4 inch wafer or one small sampel at a time. Machine is equipped with 2 gaslines: oxygen and nitrogen, but all tests run with oxygen as recommended by Diener.

Ashing of AZ MiR701 resist

You can use different strategy planing your descum: you can change power settings or you can vary chamber pressure during descum.

Testing different power settings

Recipe settings: Kept oxygen and pressure settings constant at Oxygen: 5 sccm under process; Pressure: 0,2mbar and vary power.

Experiment parameters:

|

Testing different pressure settings

Recipe settings: Kept power setting constant at Power: 100% and vary oxygen flow during process.

Experiment parameters:

|

Ashing of AZ5214E resist

Recipe settings: Kept power setting constant at Power: 100% and vary oxygen flow during process.

Experiment parameters:

|