Specific Process Knowledge/Lithography/Coaters/GammaEbeam: Difference between revisions

| (4 intermediate revisions by the same user not shown) | |||

| Line 7: | Line 7: | ||

The 2" coater station is equipped with 1 resist line, as well as 1 syringe line: | The 2" coater station is equipped with 1 resist line, as well as 1 syringe line: | ||

*AR-P 6200.09 (CSAR) | *AR-P 6200.09 (CSAR) | ||

*Syringe, which can be used for various resists (anisole-based or PGMEA-based). | *Syringe, which can be used for various resists (anisole-based or PGMEA-based). ''We currently recommend against using the syringe, as the process setup is quite demanding. Use a manual spin coater instead.'' | ||

The 4"/6" coater station is equipped with 4 different resists lines: | The 4"/6" coater station is equipped with 4 different resists lines: | ||

| Line 15: | Line 16: | ||

*AZ 4562 | *AZ 4562 | ||

The processes that are available on the system are developed by Nanolab. Upon request, it is possible to establish new processes. Use of the syringe requires special training, and | The processes that are available on the system are developed by Nanolab. Upon request, it is possible to establish new processes. Use of the syringe requires special training, and ''requires'' batch processing - it is not for processing a few wafers now and then. | ||

'''[https://www.youtube.com/watch?v=3JhM3rmLVpA Training video]''' | '''[https://www.youtube.com/watch?v=3JhM3rmLVpA Training video]''' | ||

The user manual, quality control procedures and results, user APVs, and contact information can be found in [http://labmanager.dtu.dk/function.php?module=Machine&view=view&mach=417 LabManager] - '''requires login''' | |||

===[[Specific Process Knowledge/Lithography/Coaters/Spin Coater: Gamma E-beam and UV processing|Process information]]=== | ===[[Specific Process Knowledge/Lithography/Coaters/Spin Coater: Gamma E-beam and UV processing|Process information]]=== | ||

| Line 29: | Line 30: | ||

=== Equipment performance and process related parameters === | === Equipment performance and process related parameters === | ||

{| border=" | {|border="1" cellspacing="1" cellpadding="10" style="text-align:left;" | ||

!style="background:silver; color:black;" align="center" width="60"|Purpose | !style="background:silver; color:black;" align="center" width="60"|Purpose | ||

| Line 52: | Line 53: | ||

|style="background:LightGrey; color:black"|HMDS contact angle | |style="background:LightGrey; color:black"|HMDS contact angle | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

60 - 80° (on Silicon) | 60 - 80° (on Silicon) | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Coating thickness | |style="background:LightGrey; color:black"|Coating thickness | ||

| Line 64: | Line 65: | ||

|style="background:LightGrey; color:black"|Priming temperature | |style="background:LightGrey; color:black"|Priming temperature | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

120 °C | 120 °C | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Spin speed | |style="background:LightGrey; color:black"|Spin speed | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

10 - 6000 rpm | 10 - 6000 rpm | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Spin acceleration | |style="background:LightGrey; color:black"|Spin acceleration | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

10 - 10000 rpm/s | 10 - 10000 rpm/s | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Hotplate temperature | |style="background:LightGrey; color:black"|Hotplate temperature | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

25 - 200 °C | 25 - 200 °C | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Cool plate temperature | |style="background:LightGrey; color:black"|Cool plate temperature | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

21 °C | 21 °C | ||

|- | |- | ||

!style="background:silver; color:black" align="center" valign="center" rowspan="3"|Substrates | !style="background:silver; color:black" align="center" valign="center" rowspan="3"|Substrates | ||

| Line 91: | Line 92: | ||

| style="background:LightGrey; color:black"|Allowed materials | | style="background:LightGrey; color:black"|Allowed materials | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

Silicon, III-V, and glass | Silicon, III-V, and glass | ||

Resists and crystalbond are not allowed in the HMDS module | Resists and crystalbond are not allowed in the HMDS module | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Batch | |style="background:LightGrey; color:black"|Batch | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

1 - 25 | 1 - 25 | ||

|- | |- | ||

|} | |} | ||

<br clear="all" /> | <br clear="all" /> | ||

Latest revision as of 14:29, 20 September 2023

Spin Coater: Gamma E-beam and UV

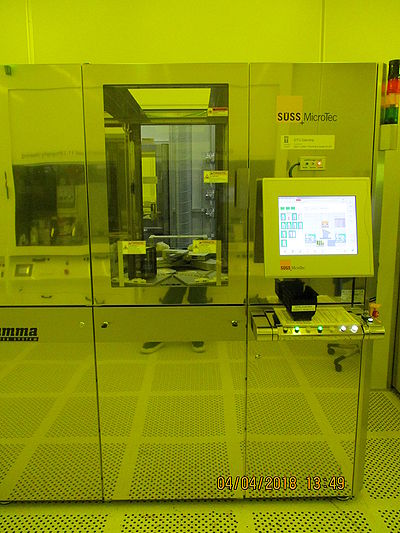

Spin Coater: Gamma E-beam and UV was installed at DTU Nanolab in June 2017. It is a Gamma 4M cluster from Süss MicroTec with spin coating, HMDS vapour priming, and baking modules. The system handles 2", 4", and 6" wafers without size conversion, using two separate coater stations.

The 2" coater station is equipped with 1 resist line, as well as 1 syringe line:

- AR-P 6200.09 (CSAR)

- Syringe, which can be used for various resists (anisole-based or PGMEA-based). We currently recommend against using the syringe, as the process setup is quite demanding. Use a manual spin coater instead.

The 4"/6" coater station is equipped with 4 different resists lines:

- AZ 5214E

- AZ MiR 701

- AR-P 6200.09 (CSAR)

- AZ 4562

The processes that are available on the system are developed by Nanolab. Upon request, it is possible to establish new processes. Use of the syringe requires special training, and requires batch processing - it is not for processing a few wafers now and then.

The user manual, quality control procedures and results, user APVs, and contact information can be found in LabManager - requires login

Process information

| Purpose |

| |

|---|---|---|

| Resist |

| |

| Performance | HMDS contact angle |

60 - 80° (on Silicon) |

| Coating thickness |

| |

| Process parameters | Priming temperature |

120 °C |

| Spin speed |

10 - 6000 rpm | |

| Spin acceleration |

10 - 10000 rpm/s | |

| Hotplate temperature |

25 - 200 °C | |

| Cool plate temperature |

21 °C | |

| Substrates | Substrate size |

|

| Allowed materials |

Silicon, III-V, and glass Resists and crystalbond are not allowed in the HMDS module | |

| Batch |

1 - 25 |