Specific Process Knowledge/Thermal Process/Oxidation: Difference between revisions

| Line 2: | Line 2: | ||

==Oxidation== | ==Oxidation== | ||

At Danchip we have seven furnaces for oxidation of silicon samples: Boron Drive-in | At Danchip we have seven furnaces for oxidation of silicon samples: Boron Drive-in + Pre-dep furnace (A1), Phosphorous Drive-in furnace (A3), Noble furnace, Anneal-oxide furnace (C1), Anneal-Bond furnace (C3), APOX furnace (D1) and Multipurpose Annealing furnace. | ||

Oxidation can take place either by a dry process or a wet process, depending on what furnace that is used for the oxidation. The film quality for a dry oxide is better than the film quality for a wet oxide with regards to density and dielectric constant. However, the oxidation rate is slow for a dry oxide. | Oxidation can take place either by a dry process or a wet process, depending on what furnace that is used for the oxidation. The film quality for a dry oxide is better than the film quality for a wet oxide with regards to density and dielectric constant. However, the oxidation rate is slow for a dry oxide. | ||

| Line 10: | Line 10: | ||

*Very thick oxide layers >4 µm can be grown in D1 by a wet oxidation (only performed by Danchip). | *Very thick oxide layers >4 µm can be grown in D1 by a wet oxidation (only performed by Danchip). | ||

The standard recipes, quality control limits and results for the Boron Drive-in + | The standard recipes, quality control limits and results for the Boron Drive-in + Pre-dep furnace (A1) and the Phosphorus Drive-in furnace (A3) can be found here: | ||

*[[Specific Process Knowledge/Thermal Process/A1 Furnace Boron drive-in|Standard recipes, QC limits and results for the Boron Drive-in + Predep furnace (A1)]] | *[[Specific Process Knowledge/Thermal Process/A1 Furnace Boron drive-in|Standard recipes, QC limits and results for the Boron Drive-in + Predep furnace (A1)]] | ||

*[[Specific Process Knowledge/Thermal Process/A3 Phosphor Drive-in furnace|Standard recipes, QC limits and results for the Phosphorus Drive-in furnace (A3)]] | *[[Specific Process Knowledge/Thermal Process/A3 Phosphor Drive-in furnace|Standard recipes, QC limits and results for the Phosphorus Drive-in furnace (A3)]] | ||

The wet oxidation rates for the Anneal-Bond furnace (C1) can be found here: | |||

*[[Specific Process Knowledge/Thermal Process/Oxidation/Wet oxidation C1 furnace|Wet oxidation in Anneal-oxide furnace (C1)]] | *[[Specific Process Knowledge/Thermal Process/Oxidation/Wet oxidation C1 furnace|Wet oxidation in Anneal-oxide furnace (C1)]] | ||

Revision as of 16:01, 5 August 2015

Feedback to this page: click here

Oxidation

At Danchip we have seven furnaces for oxidation of silicon samples: Boron Drive-in + Pre-dep furnace (A1), Phosphorous Drive-in furnace (A3), Noble furnace, Anneal-oxide furnace (C1), Anneal-Bond furnace (C3), APOX furnace (D1) and Multipurpose Annealing furnace.

Oxidation can take place either by a dry process or a wet process, depending on what furnace that is used for the oxidation. The film quality for a dry oxide is better than the film quality for a wet oxide with regards to density and dielectric constant. However, the oxidation rate is slow for a dry oxide.

- Dry oxidation is used for 5 nm - 200 nm of oxide and can be grown in the furnaces: A1, A2, A3, C1, C3, Multipurpose Annealing

- Wet oxidation is used for up to 4 µm of oxide and can be grown in the furnaces: A1, A3, D1.

- Very thick oxide layers >4 µm can be grown in D1 by a wet oxidation (only performed by Danchip).

The standard recipes, quality control limits and results for the Boron Drive-in + Pre-dep furnace (A1) and the Phosphorus Drive-in furnace (A3) can be found here:

- Standard recipes, QC limits and results for the Boron Drive-in + Predep furnace (A1)

- Standard recipes, QC limits and results for the Phosphorus Drive-in furnace (A3)

The wet oxidation rates for the Anneal-Bond furnace (C1) can be found here:

Comparison of the seven oxidation furnaces

| Generel description | Drive-in of boron deposited in the same furnace or drive-in of ion implanted boron. Can also be used for dry and wet oxidation. | Oxidation of gate-oxide and other very clean oxides. | Drive-in of phosphorous deposited in the phosphorous pre-dep furnace (A4) or drive-in of ion implanted phosphorous. Can also be used for dry and wet oxidation. | Oxidation of 4" and 6" wafers. Oxidation of new wafers without RCA cleaning. Oxidation of wafers from the LPCVD furnaces and PECVD2. | Oxidation of wafers from EVG-NIL, PECVD3 and wafers with aluminum. | Oxidation of very thick oxides, thickness higher than 4 µm. | Oxidation of almost all materials on silicon wafers. |

|---|---|---|---|---|---|---|---|

| Oxidation method |

|

|

|

|

|

|

|

| Annealing gas |

|

|

|

|

|

|

|

| Process temperature |

|

|

|

|

|

|

|

| Substrate and Batch size |

Including one test wafer |

Including one test wafer |

Including one test wafer |

Including one test wafer |

Including one test wafer |

|

|

| Allowed materials |

All wafers have to be RCA cleaned, except for boron pre-doped wafers from the same furnace. |

All wafers have to be RCA cleaned. |

All wafers have to be RCA cleaned, except for phosphorous pre-doped wafers from furnace A4. |

All processed wafers have to be RCA cleaned, except for wafers from LPCVD furnaces and PECVD2. |

All wafers have to be RCA cleaned, except for wafers from EVG-NIL, PECVD3 and wafers with aluminum. |

Only new wafers |

Almost all materials, permission is needed |

Oxidation curves

Color chart for oxide/nitride thickness

Generic calculator for wet/dry oxide thickness calculation

The following links give an approximate oxide time/thickness based on a general formula:

Deal-Grove parameters

By Kasper Reck-Nielsen February 2015

The following table contains linear and parabolic parameters for use in the Deal-Grove model for thermal oxidation. The parameters are obtained a least squares fit to data available in the furnace logbooks. Information on wafer orientation and doping concentration, which is not available in the logbooks, has not been included in calculating the parameters.

| Anneal Oxide | Anneal Bond | Boron Drive-in | Gate Oxide | Phosphor Drive-in | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Recipe | B [µm2/h] | B/A [µm/h] | RMSE [nm] | B [µm2/h] | B/A [µm/h] | RMSE [nm] | B [µm2/h] | B/A [µm/h] | RMSE [nm] | B [µm2/h] | B/A [µm/h] | RMSE [nm] | B [µm2/h] | B/A [µm/h] | RMSE [nm] |

| DRY900 | 0.000408 | 0.107 | Too little data | 0.0660 | 0.272 | 31 | 0.000390 | 0.154 | Too little data | 0.0028 | 0.079 | 4 (limited data) | 0.0507 | 0.884 | Too little data |

| DRY1000 | - | - | - | - | - | - | 0.465 | 0.838 | 20 | - | - | - | 0.641 | 1.45 | 41 |

| DRY1050 | 0.0111 | 0.526 | 27 | - | - | - | 0.0129 | 0.330 | 8 | 0.022 | 0.505 | 3 (limited data) | 0.0134 | 0.362 | 6 |

| DRY1100 | 0.020 | 0.930 | 10 | - | - | - | 0.0212 | 0.736 | 23 | - | - | - | 0.0313 | 0.553 | 14 |

| WET950 | - | - | - | - | - | 0.0716 | 1.25 | 12 | - | - | - | 0.110 | 1.17 | 11 | |

| WET1000 | 0.192 | 1.54 | 44 | - | - | 0.192 | 1.80 | 29 | - | - | - | 0.195 | 2.49 | 22 | |

| WET1050 | 0.487 | 0.965 | 29 | 0.477 | 0.899 | Too little data | 0.455 | 1.33 | 16 | - | - | - | 0.448 | 1.73 | 12 |

| WET1100 | 0.580 | 1.43 | 8 | - | - | - | 0.519 | 1.186 | 3 | - | - | - | 0.403 | 9.05 | 7 |

Wet Oxidation on <100>

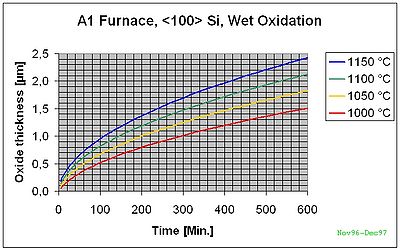

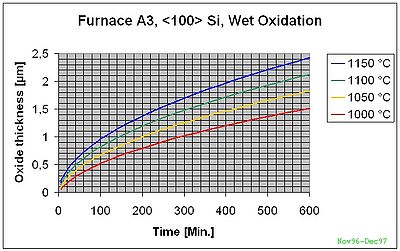

The curves below are based on measurements in our specific furnaces and give more accurate results. We will still recommend to make minimum one test run if the thickness is very important.

- Wet oxidation

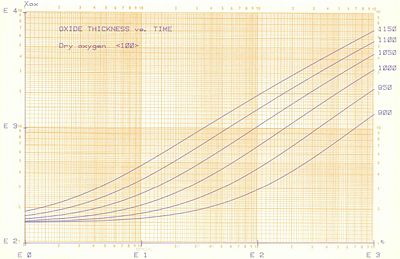

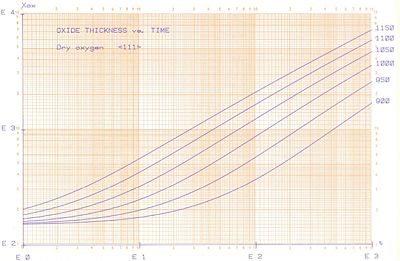

Dry Oxidation on <100> and <111> wafer

- Dry oxidation