Specific Process Knowledge/Lithography/EBeamLithography/JEOL 9500 User Guide

Purpose, location and technical specifications

Type and location of machine

The JEOL JBX-9500FS electron beam lithography system is a spot electron beam lithography system designed for use in writing patterns (10 nm - 1 µm) in electron sensitive resists. The JEOL JBX-9500FS was purchased in 2012 and is installed in E-1 and E-2 at DTU Nanolab. The main console of the e-beam writer is installed in E-2 which is a class 10 (ISO 4) cleanroom with tight temperature and moisture control. The computer controlling the e-beam (EWS/9500) and the computer supporting the conversion of e-beam files are located in E-1 which is a class 100 (ISO 5) cleanroom.

Training and authorization

- Only authorized users are allowed to use this machine.

- In E-2, all users must keep within the area between the front side of the machine and the table with the pre-aligner setup. Only JEOL staff or DTU Nanolab staff may access the backside of the machine.

- No users, not even authorised users, are allowed to load a substrate into the automatic cassette transfer system.

- After your exposure, fully trained users can unload their cassettes from the automatic cassette transfer system and unmount their substrates.

- If you are unable to unmount your substrates before another user requires the cassette, you must accept that either the next user or DTU Nanolab personel unmount your substrates.

- Training can be requested by sending a mail with relevant process flow to training@nanolab.dtu.dk

Original JEOL Manual

The original JEOL manual for the e-beam writer JEOL JBX-9500FS is located on the O-drive: O:\CleanroomDrive\_Equipment\E-beam

Techical Specification

The system can be characterized as follows:

- The spot beam for electron beam writing is generated by a ZrO/W emitter and a four-stage electron beam focusing lens system.

- The maximum frequency of the deflector scanner is 100 MHz, i.e. the minimum beam dwell time is 10 ns.

- The acceleration voltage is locked at 100 kV.

- The e-beam writer can pattern structures with a minimum resolution of 10 nm.

- The maximum writing field size is 1000 µm x 1000 µm.

- The machine has cassettes for 2", 4", 6" and 8" wafers and also dedicated cassettes for chips with slot dimensions of 4 mm, 8 mm, 12 mm, and 20 mm. See the Cassette specification page for more information.

Sample mounting

The JEOL 9500 system uses a proprietary sample cassette format and thus each sample must be mounted in an appropriate cassette. Cassettes are available for wafer sizes from 2” to 8”. Smaller chips must be mounted in dedicated chip cassettes with slots of four different sizes available. For more information on available cassettes and their specifications please refer to the JEOL 9500 cassette specifications page.

For the tutorial job we are using a 4" wafer and hence it must be mounted in one of the 4” cassettes, in this case the 4" aluminium cassette (BM2P-011). If a cassette has been used recently it might be found on the cassette preparation table already, otherwise it will have to be retrieved from the cassette transfer system. This is done from the operation screen of the cassette transfer system.

| |

|

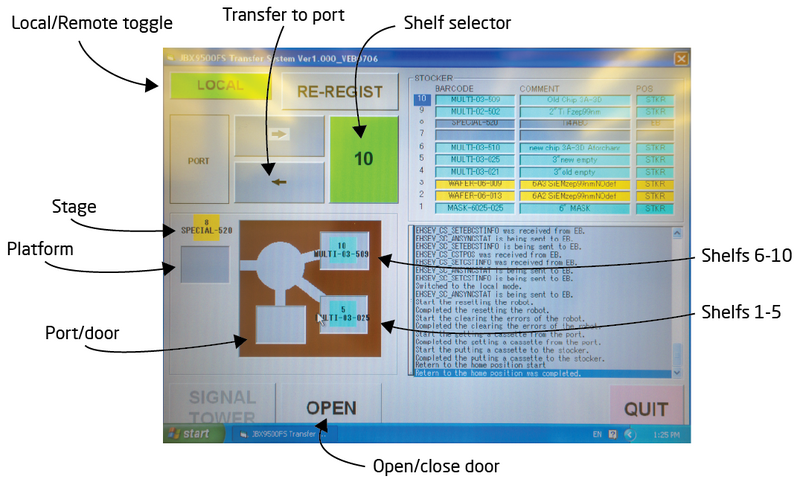

Operation screen of the automatic cassette transfer system / auto stocker. Photo: Thomas Pedersen. | |

Retrieving a cassette from the automatic cassette transfer system

- Toggle the system to "Local" operation mode

- Identify the shelf number for the cassette in question

- Use the "shelf selector" to choose that number

- Press the transfer button to transfer it from the shelf to the port/door

- Once the robot is done, click "Open" to unlock the door

- Open door, retrieve cassette and place it on a layer of tissues on the cassette preparation table

- Close the door

- Click "Close" to lock the door

- Set the system back to "Remote" operation

Once the cassette is placed up-side down on the preparation table the slot cover can be removed by pressing down and rotating the spring loaded locking mechanism. The substrate can be placed in the slot using the vacuum tweezer found on the table. As the cassette is up-side down, the substrate must be loaded with resist side down.

|

|

|

Samples can be loaded into appropriate cassettes on the cassette preparation table. Photo: Thomas Pedersen. | |

The system is fitted with an auto stocker system that can store 10 cassettes. It is thus possible to prepare multiple substrates and define an automated job to execute exposure of several substrates across several cassettes. After sample loading the cassette must be placed in the automatic cassette transfer system. Users are NOT allowed to do this. Only Nanolab staff who are members of the E-beam Loading Team may place cassettes into the automatic cassette transfer system. Hence users must always contact the Nanolab E-beam loading team prior to exposure to have their cassette loaded into the cassette transfer system. The E-beam loading team can be contacted at [email]. Upon loading a cassette Nanolab staff will visually verify the sample has been installed and secured correctly. Incorrect sample mounting can lead to severe damage to the internal parts of the JEOL 9500 exposure system.

|

|

Nanolab staff member loading the 4" wafer cassette to the automatic cassette transfer system. Photo: Thomas Pedersen. |