Specific Process Knowledge/Thermal Process/Oxidation/Breakdown voltage measurements: Difference between revisions

| Line 36: | Line 36: | ||

<gallery caption="A1 furnace, dry oxidation" widths="600px" heights="400px" perrow="2"> | <gallery caption="A1 furnace, dry oxidation" widths="600px" heights="400px" perrow="2"> | ||

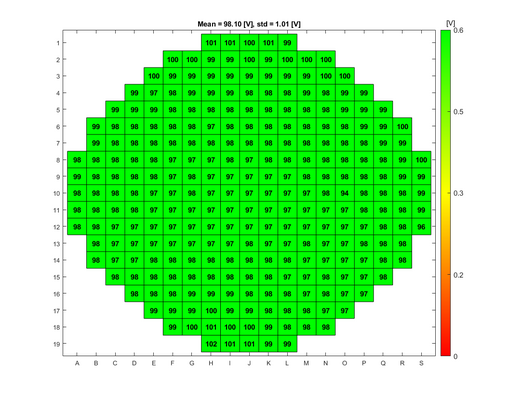

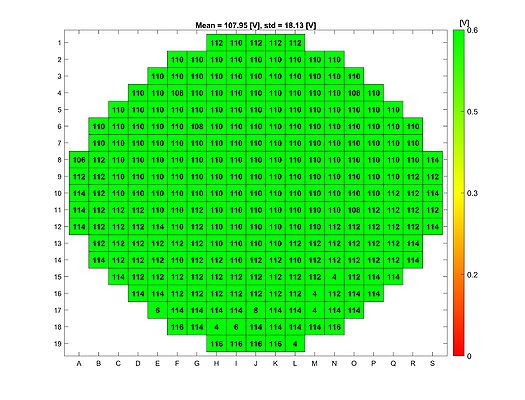

image:2021-11-02_14-32-24_Wafer_3_A1_DRY1050_100nm_Abs.png|Absolute breakdown voltage | image:2021-11-02_14-32-24_Wafer_3_A1_DRY1050_100nm_Abs.png|'''Absolute breakdown voltage''' | ||

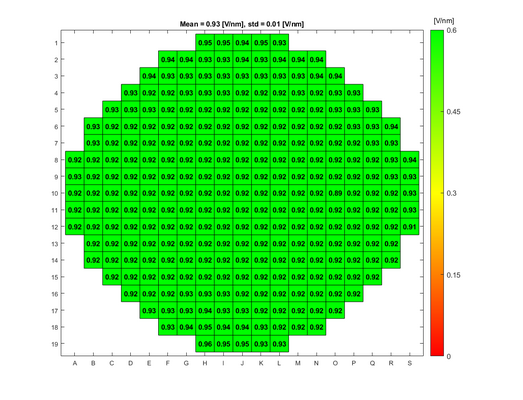

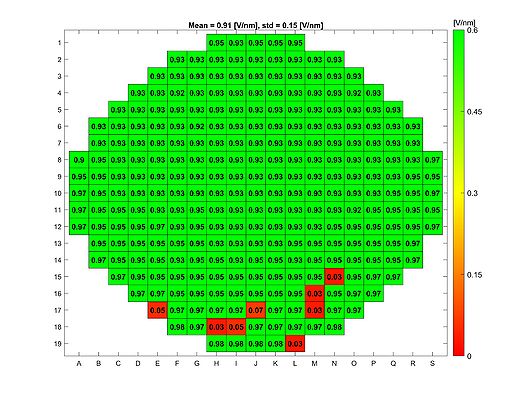

image:2021-11-02_14-32-24_Wafer_3_A1_DRY1050_100nm_Rel.png|Relative breakdown voltage | image:2021-11-02_14-32-24_Wafer_3_A1_DRY1050_100nm_Rel.png|'''Relative breakdown voltage''' | ||

</gallery> | </gallery> | ||

===Breakdown voltage measurements for wet oxide=== | ===Breakdown voltage measurements for wet oxide=== | ||

Revision as of 15:50, 1 December 2021

THIS PAGE IS UNDER CONSTRUCTION

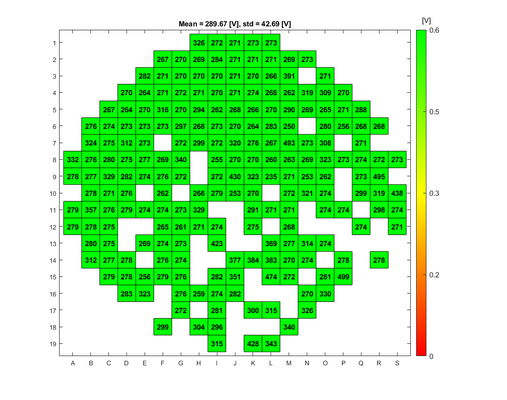

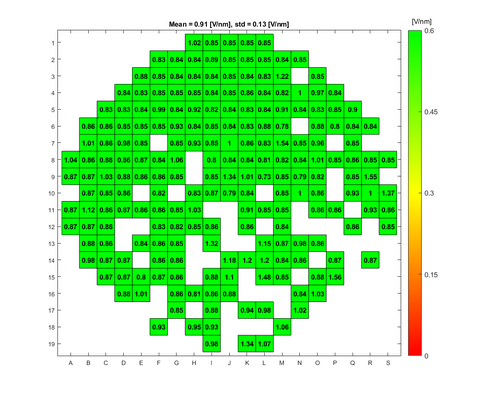

In order to evaluate the quality of the the oxide layer, the breakdown voltage has been measured for both wet and dry oxide grown in the A1 Boron Drive-in and Pre-dep and the A3 Phosphorus Pre-dep furnace.

The breakdown voltage measurements were performed using a automated measure setup building at DTU Health Tech. This setup automatically measures the breakdown voltage in pattern over the wafers. Measuring breakdown voltage is done by applying an increasing reverse voltage to the device until a certain test current is reached that indicates that the device is in breakdown

Both absolute breakdown voltage has been measured, and the relative breakdown voltage has been calculated. The relative breakdown voltage is the breakdown voltage per thickness.

The measurements were made in November 2021.

Procedure

The procedure for the breakdown voltage measurements is the following:

- RCA clean new wafers

- Grow wet or dry oxide in the A1 or A3 furnace

- Remove the oxide layer on the back of the wafers. Use plasma etching or BHF etching (protect the front of the wafer with blue tape).

- Lithography and lift-off or metal deposition using a shadow mask?

Breakdown voltage results for the A1 Boron Drive-in and Pre-dep furnace

Breakdown voltage measurements for dry oxide

Oxidation parameters:

- Temperature: 1050 C

- Oxidation time: 1 h 40 min

- Annealing time: 20 min

Oxide thickness: ~100 nm

- A1 furnace, dry oxidation

Breakdown voltage measurements for wet oxide

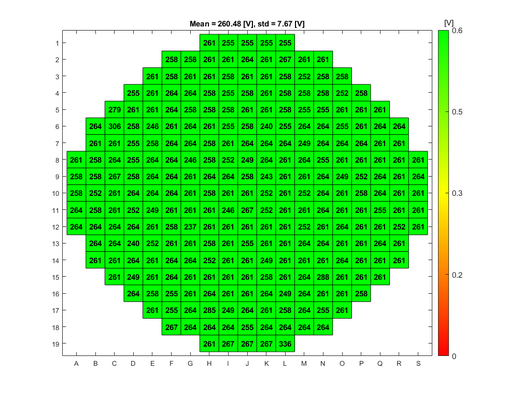

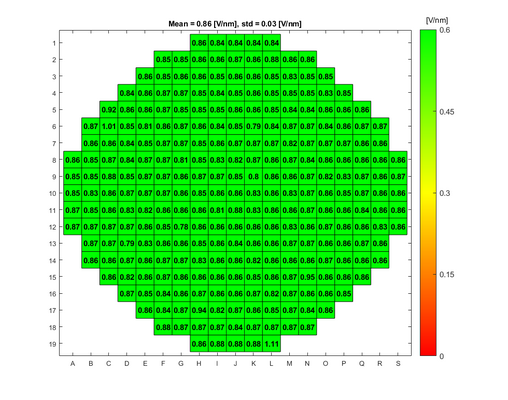

Oxidation parameters:

- Temperature: 1050 C

- Oxidation time: 30 min

- Annealing time: 20 min

Oxide thickness: ~300 nm

- A1 furnace, wet oxidation

The measurement have been made in November 2021.

Breakdown voltage results for the A3 Phosphorus Drive-in furnace

Right before the breakdown voltage measurements were made, all quartz parts in the furnace were changed.

Breakdown voltage measurements for dry oxide

Oxidation parameters:

- Temperature: 1050 C

- Oxidation time: 1 h 40 min

- Annealing time: 20 min

Oxide thickness: ~110 nm

- A3 furnace, dry oxidation

Breakdown voltage measurements for wet oxide

Oxidation parameters:

- Temperature: 1050 C

- Oxidation time: 30 min

- Annealing time: 20 min

Oxide thickness: ~320 nm

- A3 furnace, wet oxidation

The measurement have been made in November 2021.